20m³ PSA air separation oxygen generator for hospital

A PSA oxygen generator for hospital is a device that produces high-purity oxygen gas from ambient air. It is commonly used in various industries and applications, including medical facilities, industrial processes, and even for military purposes.

Product Description

20m³ PSA air separation oxygen generator for hospital

A 20m3/h PSA (Pressure Swing Adsorption) air separation oxygen generator for hospitals is a device designed to produce medical-grade oxygen on-site, typically within a hospital setting.

Components and functions of PSA air separation oxygen generator

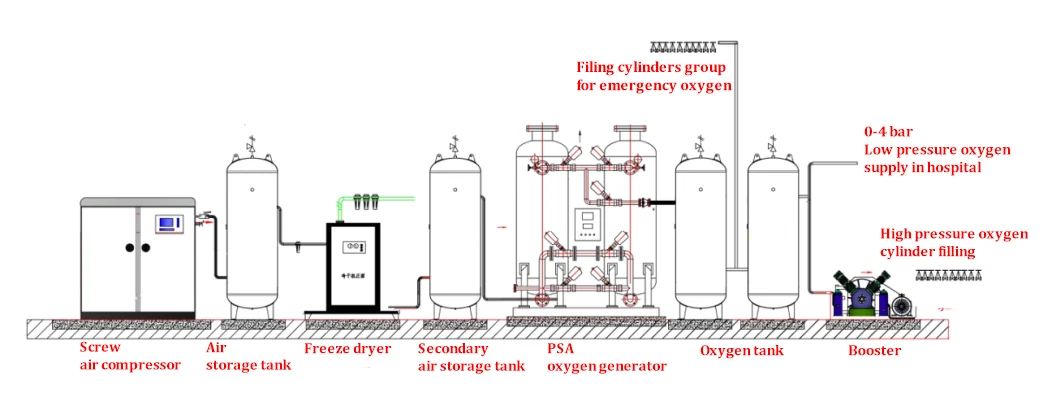

- PSA Technology: PSA technology is a widely used method for separating oxygen from air. It operates based on the principle of adsorption, where oxygen molecules are selectively captured from compressed air by a molecular sieve material while other gases, such as nitrogen, are allowed to pass through.

- Air Compressor: The system starts with an air compressor that takes in ambient air and compresses it to the required pressure for the PSA process. This compressed air is then fed into the PSA unit.

- Adsorption Towers: The heart of the PSA system consists of adsorption towers filled with a specialized adsorbent material, typically zeolite or activated carbon. These towers alternate between adsorption and desorption cycles to separate oxygen from the compressed air stream.

- Cycle Controller: A control system governs the cycling of the adsorption towers. It controls the flow of air into the towers, the pressure levels, and the switching between adsorption and desorption phases to ensure efficient oxygen production.

- Oxygen Buffer Tank: Once oxygen is separated from the air, it’s collected in a buffer tank. This tank ensures a steady supply of oxygen even during fluctuations in demand.

- Purity Analyzer: A purity analyzer continuously monitors the oxygen output to ensure it meets medical-grade standards (typically 93% purity or higher).

- Filters and Dryers: The system includes filters and dryers to remove impurities, moisture, and other contaminants from the compressed air before it enters the adsorption towers. This ensures the purity of the generated oxygen.

- Safety Features: Various safety features are incorporated into the system to prevent over-pressurization, leaks, or other potential hazards. These may include pressure relief valves, alarms, and automatic shutdown mechanisms.

- Remote Monitoring and Control: Some modern systems may offer remote monitoring and control capabilities, allowing hospital staff or maintenance personnel to monitor the system’s performance and make adjustments as needed from a central location.

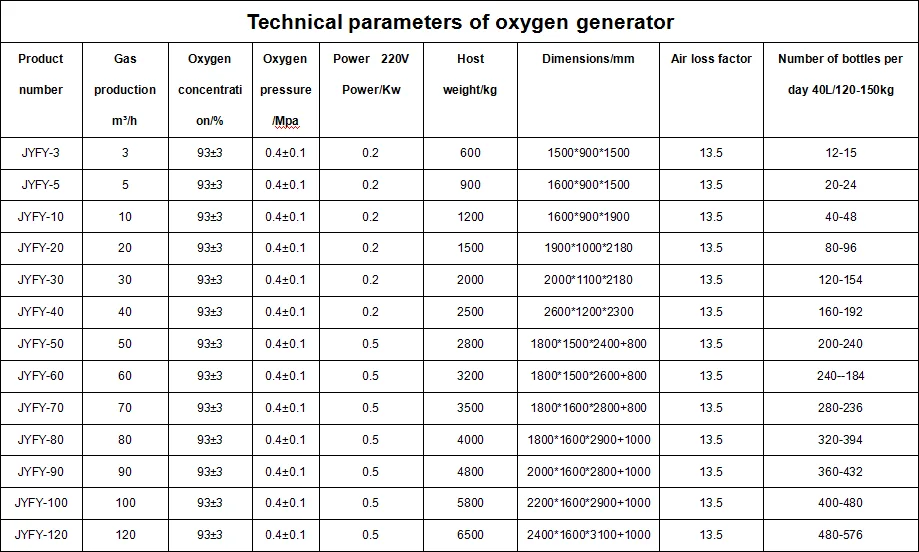

Technical indicators of the oxygen generator:

● Oxygen flow rate: 3-200 m3/h

● Oxygen purity: 25-93%

● Oxygen pressure: 0.45-0.6 MPa

● Dew point: -50

● Purity:93±3%

FAQ:

Whether you could make our brand on your products?

A: Yes. We can print your Logo on both the products and the packages if you want.

How to guarantee the quality of your products?

A: 1.Strict detection during production.

2. Before ship we test the equipment, make sure it’s work well.

Produce time?

A: about 30 days